Case Study

Advancing Restorative Dentistry with 3D Printed Hybrid Ceramics

Restorative dentistry is undergoing a pivotal evolution, driven by the integration of 3D printed hybrid ceramic restorations into everyday clinical practice. In our experience, these restorations offer a clear step forward in both efficiency and precision. After completing thousands of prints, we’ve consistently found that 3D printed inlays, onlays, and crowns outperform traditional direct resin and CEREC-milled alternatives in workflow and clinical reliability. In this case study, we share our experience using this technology to improve clinical results.

Workflow optimisation

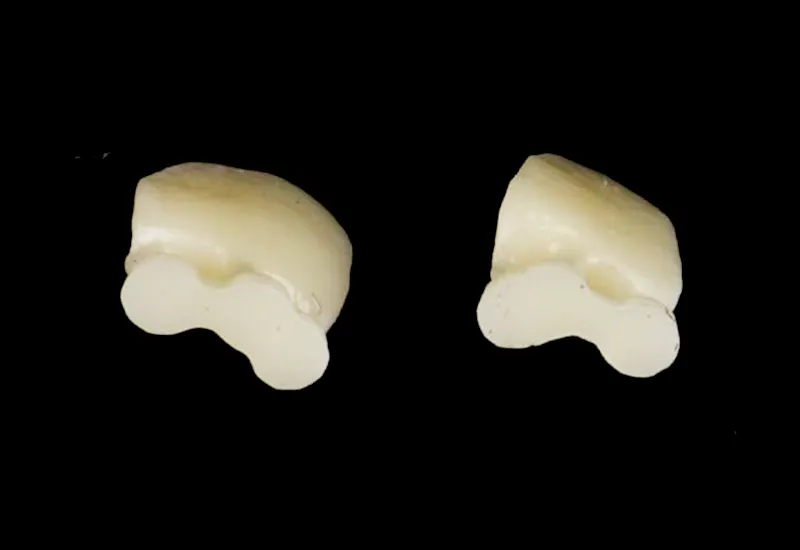

One of the biggest perks of 3D printed hybrid ceramics is how much they streamline the entire restorative process. Using the Medit i700 intraoral scanner, we can capture a precise digital impression in just three minutes—a major improvement over traditional physical impressions. Designing the restoration in Medit CliniCAD takes about the same time, and the SprintRay Pro 55s 3D printer produces the restoration in only 11 minutes, cutting down chairside time dramatically. After printing, the post-print steps—washing, staining, and curing—are done in just 5.5 minutes using the SprintRay NanoCure system.

Overall, the time savings compared to traditional methods are outstanding, without compromising on the quality or durability of the restorations. This efficient workflow allows for better patient experiences and increases the capacity for same-day restorative procedures.

The effectiveness of hybrid ceramics

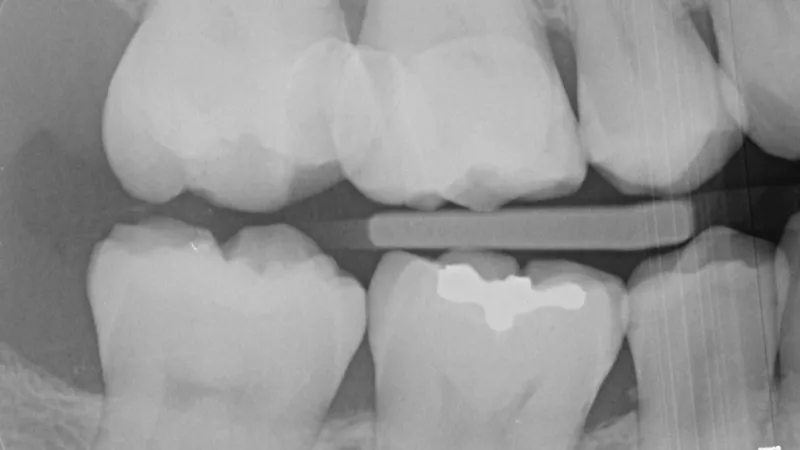

When comparing 3D printed hybrid ceramics with direct resin restorations, a major benefit emerges in terms of durability and performance. Direct resin restorations, while commonly used, have inherent limitations. As highlighted by a recent systematic review and meta-analysis, each additional surface added to a direct resin restoration increases the failure rate by 30–40%. This is particularly relevant in complex restorations that involve multiple surfaces, where the likelihood of failure escalates.

In contrast, indirect onlay restorations made of hybrid ceramics or resins have been shown to perform with the same success as ceramic restorations, according to research. Both materials outperform direct resin, offering increased longevity and a reduced risk of failure, making hybrid ceramic restorations an ideal choice for complex cases.

Material insights and clinical applications

The material used for 3D printed restorations is a methacrylate/acrylate polymer infiltrated with ceramic, offering mechanical and aesthetic properties similar to GC Cerasmart—a well-established milled composite. While compositionally alike, the key distinction lies in the production method: 3D printed restorations are additively manufactured, allowing for greater design flexibility and faster turnaround. When used for inlays and medium-sized onlays, these hybrid ceramics have demonstrated clinical longevity comparable to that of traditional ceramic crowns, as supported by studies on indirect composites and other hybrid materials.

While hybrid ceramics perform well in partial coverage restorations, their use in full-coverage crowns warrants caution. Clinical outcomes with materials like Lava Ultimate in CEREC systems have shown that using hybrid ceramics in full-crown indications—where they were not originally intended—can lead to early failures. These experiences highlight the need for thoughtful material selection based on case complexity, load-bearing demands, and long-term expectations.

Proper handling and post-print process

One often overlooked but essential step in working with 3D printed hybrid ceramics is the post-print process. Like any resin-based restoration, these materials need meticulous handling, especially during curing. Proper curing is key to ensuring the restoration’s strength and biocompatibility. If the curing isn’t thorough, it can result in incomplete polymer conversion, which affects durability

Composite materials typically achieve a conversion rate of only 50–70% when cured intraorally, which is why printed restorations should be cured in a controlled environment. The rigorous testing and approval processes by regulatory bodies such as the Therapeutic Goods Administration (TGA) further highlight the need for precise adherence to post-print protocols.

The rise of 3D printed hybrid ceramics

3D printed hybrid ceramics mark a significant advancement over traditional direct resin restorations, especially for complex cases involving multiple surfaces. As digital workflows mature, these restorations are no longer emerging—they’re becoming the new standard. To maximise the potential of 3D printed hybrid ceramics, proper handling is critical—especially adherence to rigorous post-print processes such as curing. When used correctly, these materials deliver reliable outcomes and unlock new possibilities for efficient, high-quality chairside dentistry.

What a great time to be a dentist!