Case Study

3D Printed Hybrid Ceramic Onlay

Conservative restorative approach

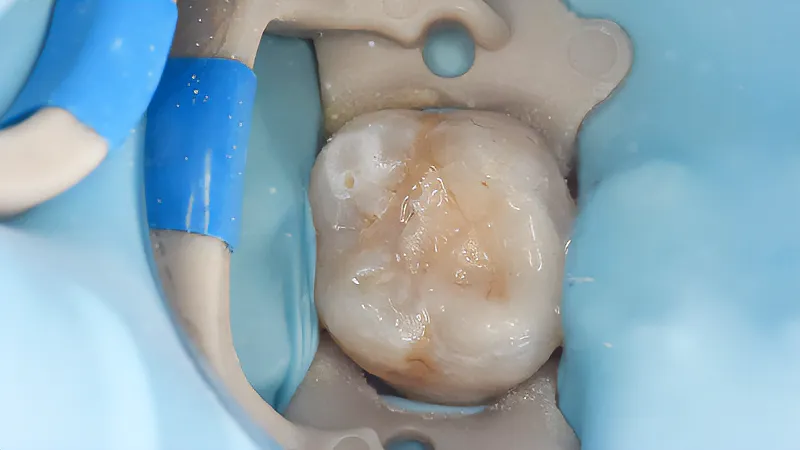

Our patient presented with an old composite restoration placed 18 years ago. The tooth exhibited an initial caries bomb from the fissure, with mild crazing cracks observed on the mesial wall in enamel but without staining. A critical consideration in this case was the preservation of the mesial gingival tissue, which appeared healthy. Given the depth of the initial carious defect, aggressive preparation could have resulted in a subgingival margin, potentially compromising soft tissue health.

Treatment plan and material selection

Our decision to utilise a 3D printed hybrid ceramic onlay instead of a conventional milled MO CEREC restoration was driven by several key factors:

Treatment plan and material selection

Our decision to utilise a 3D printed hybrid ceramic onlay instead of a conventional milled MO CEREC restoration was driven by several key factors:

- Minimally invasive approach: With advancements in digital dentistry, our goal was to conserve as much natural tooth structure as possible while ensuring a predictable, durable restoration.

- Fibre reinforcement: To address the mild mesial enamel craze line, internal reinforcement was provided using Ribbond fibre within the resin to enhance structural support and improve longevity.

- Material properties: The selected 3D printed resin (OnX Tough 2.0 A2) exhibits superior wear resistance and occlusal dampening effects, mitigating force transmission to a potentially weakened substructure.

- Precision in margins: The ability to print chamfer margins at 250 microns is a significant advantage over milled porcelain, enhancing adaptation and marginal integrity.

- Enhanced bonding capability: A freshly printed onlay provides a chemically active fitting surface with free radicals ready for optimal bonding, allowing for potential composite incorporation to form a hybrid restoration.

Procedure

1. Preparation:

The existing composite was carefully removed, and the cavity was refined to maintain a conservative preparation. The mesial enamel wall was reinforced internally using Ribbond fibre embedded in composite resin to enhance structural integrity.

2. Digital workflow:

- High-resolution intraoral scanning was performed to capture accurate digital impressions.

- The onlay design was optimised for occlusion and marginal integrity.

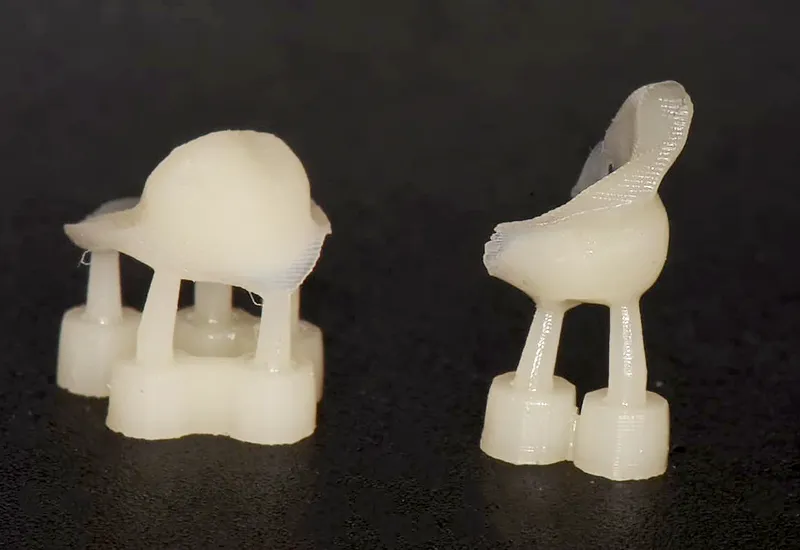

- Printing was carried out using the SR Pro2 printer with OnX Tough 2.0 A2 resin.

3. Processing:

- Print Time: 7 minutes

- Post-Processing Time: 5 minutes

- Curing: 6 minutes x2 cycles

4. Characterisation and bonding:

- Staining was performed using Empress Direct mixed with OT2 to achieve seamless integration with natural dentition.

- The onlay was bonded using a total-etch adhesive technique, ensuring maximum retention and durability.

Outcome and considerations

The final restoration exhibited excellent adaptation, aesthetics, and functional integrity. The printed hybrid ceramic onlay effectively mimicked natural tooth wear characteristics while offering superior resistance to occlusal forces. The decision to avoid a deep mesial margin ensured that gingival health was maintained, preventing potential complications associated with subgingival restorations.

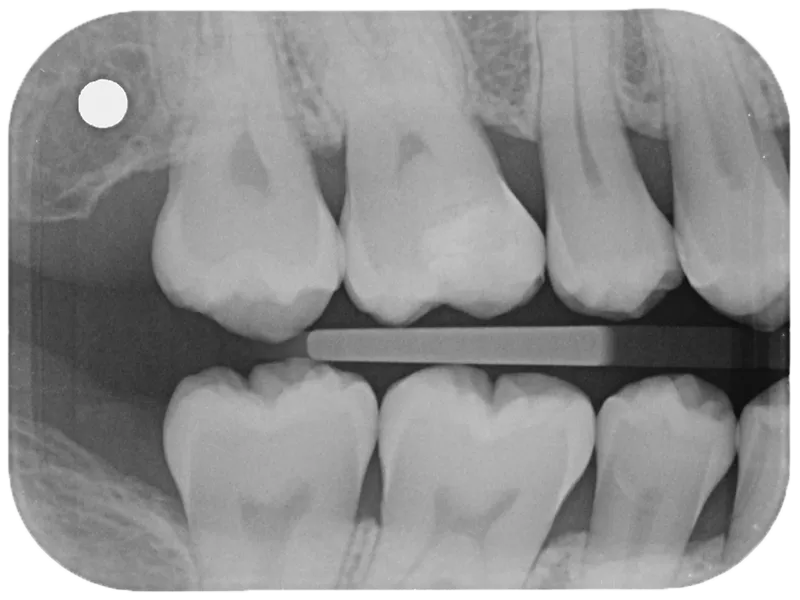

The X-ray reveals a well-adapted, conservatively placed restoration with optimal translucency for a more natural radiographic appearance.

This case reinforces the paradigm shift in restorative dentistry—leveraging advanced 3D printing technology allows us to achieve high-strength, conservative restorations that prioritise biological preservation. As material science continues to evolve, embracing these digital workflows enables us to refine our treatment approaches and elevate patient care standards.

This is digital dentistry done right: precise, conservative, and beautifully functional

With the increasing accessibility of 3D printing in dentistry, hybrid ceramic restorations present a compelling alternative to traditional milling techniques. The ability to achieve precise margins, superior occlusal adaptation, and enhanced bonding properties position this approach as a viable solution for conservative, high-performance restorations.

This case shows what’s possible when advanced materials meet smart workflows.

3D printed hybrid ceramic onlays aren’t just the future—they’re already raising the bar.